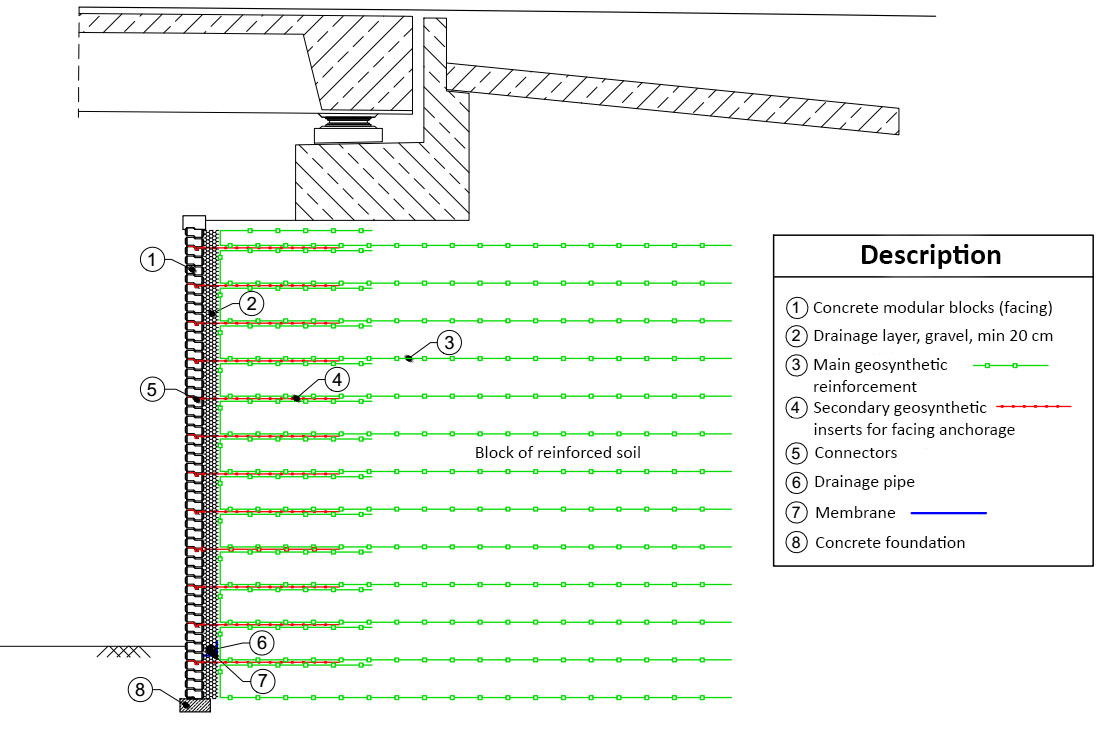

Complete reinforced earth abutments

For decades, bridge abutments and supports have been built in the form of reinforced earth all over the world. This technology significantly reduces the investment costs. The block of reinforced earth is build practically to the full height of the abutment. The only reinforced concrete element (traditional monolithic technology) in a such structure is the main beam resisting on a block from reinforced earth, which supports the spans of the structure and the transition plate.